The Environmental Partnership’s sixth annual report highlights the U.S. oil and natural gas industry’s collaborative efforts to reduce methane emissions and advance environmental progress. In 2023, participating companies achieved measurable results across all performance programs, building on the industry’s progress in reducing methane emissions, which declined 37% across U.S. onshore production regions between 2015 and 2022, according to the U.S. Environmental Protection Agency.

The Environmental Partnership, whose members represent nearly 70% of U.S. onshore oil and gas production, plays an instrumental role in supporting companies in their efforts to improve the industry’s environmental performance. The partnership fosters collective efforts that are built on sharing practices and leveraging knowledge between operators, partnering with other experts to further industry understanding, and working together to identify solutions, innovations and practices that reduce methane emissions across the supply chain.

See our progress in the 2024 Annual Report (19.8 MB).

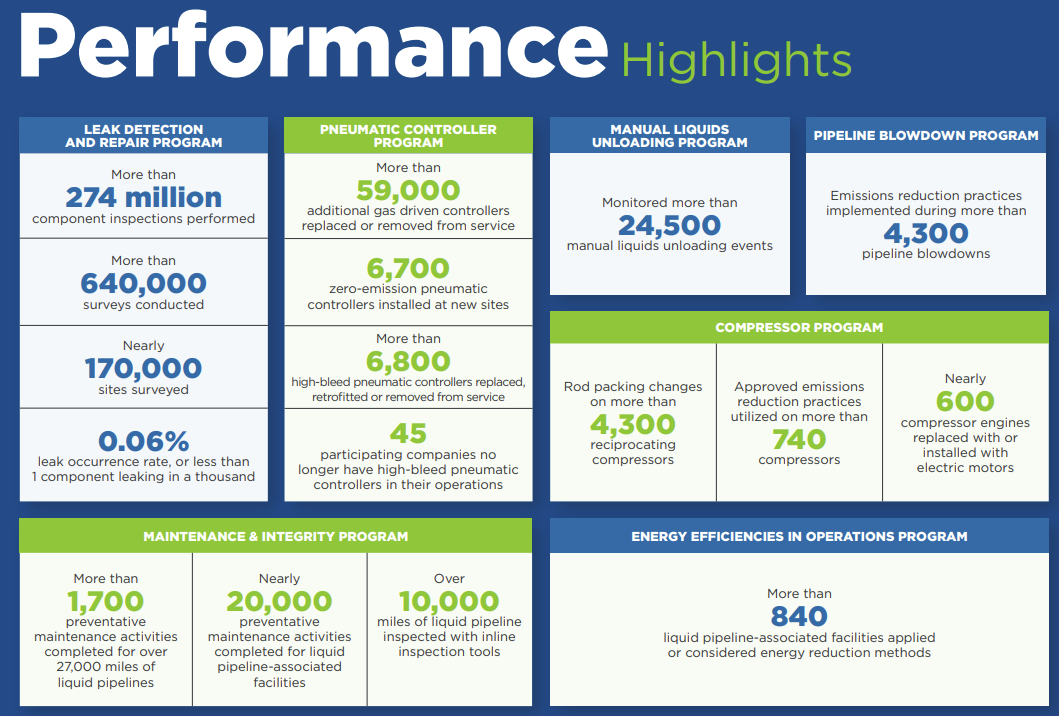

2023 Performance Highlights

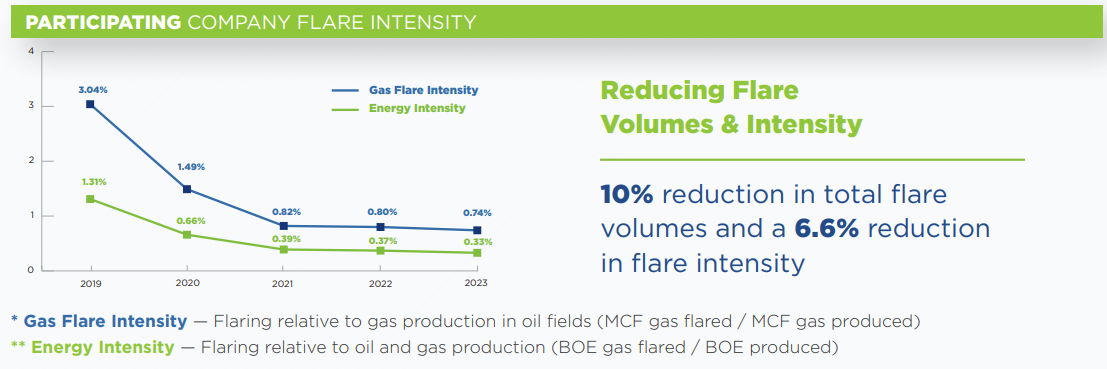

Reducing Flaring Even as Production Has Increased

In 2023, participants in The Environmental Partnership demonstrated their continued commitment to improvement by achieving a 6.6% reduction in flare intensity and a 10% reduction in total flare volumes from the previous year. Since 2019, members have reduced their reported flare volumes by more than 75%, even as oil and natural gas production has increased.

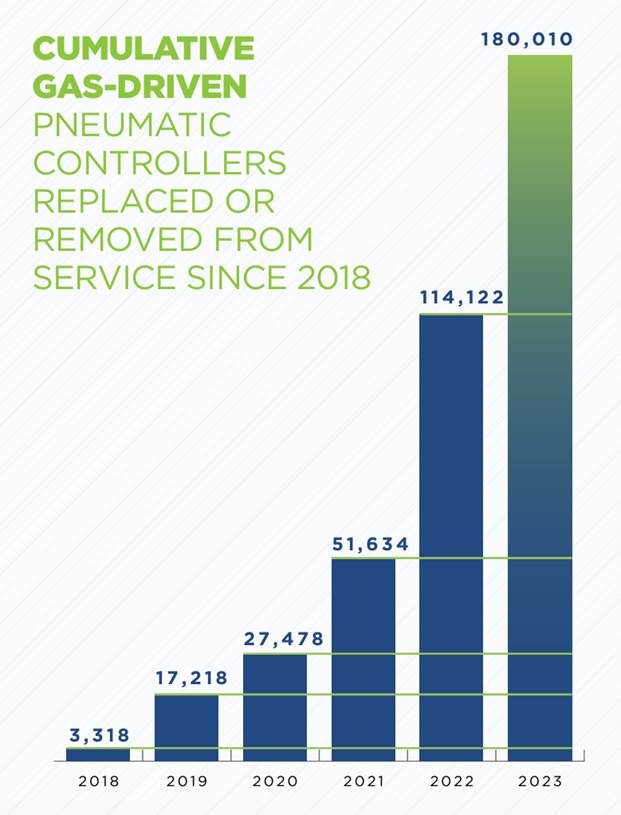

Replacing Pneumatic Controllers

Since 2018, The Environmental Partnership’s participants have removed or replaced more than 180,000 gas-driven pneumatics, resulting in the permanent reduction of an estimated 355,421 metric tonnes of methane emissions per year released into the atmosphere based on EPA’s mandatory emissions reporting requirements in place in 2023.

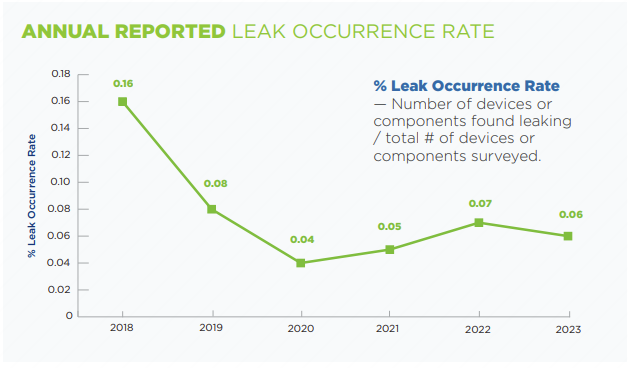

Enhancing Detection and Monitoring Strategies

Participants are exploring a variety of technologies and monitoring strategies to improve detection and prevention of emissions. By implementing robust leak detection and repair programs, companies have reduced their leak occurrence rate from a reported 0.16% in 2018 to a reported 0.06% in 2023, or less than one component leaking in 1,000.

Taking Action to Drive Meaningful Reductions in Emissions

Through TEP, we foster collective efforts that are built on sharing practices and leveraging knowledge between operators, partnering with other experts to further industry understanding, and working together to identify solutions, innovations and practices that reduce methane emissions. These efforts help accelerate all companies’ environmental efforts and build on the industry’s progress in reducing methane emissions.

In 2023, we worked with key external partners on emission reduction and research initiatives and hosted workshops and meetings across the country to allow participants to convene, learn, and share valuable information about new strategies and technologies to drive down emissions.

“The success of industry-led initiatives like The Environmental Partnership further demonstrates our industry’s unwavering commitment to reducing methane emissions across the supply chain while helping to ensure the continued production of affordable and reliable energy. From advancements in detecting and measuring emissions to sharing operational solutions, I am proud of how our participating companies are continuing to raise the bar in our collective efforts to achieve meaningful emissions reductions.”

Emily Hague

TEP Director

“It’s been a transformational year for our industry with new challenges and opportunities, but what remains clear is the commitment of program participants to reducing methane emissions. I am excited by what we’ve accomplished over the past year and look forward to the continued progress this industry-leading partnership is positioned to achieve in the years ahead.”

Vanessa Ryan

Chevron and TEP Chair

“As emissions detection technologies have evolved rapidly over the last couple of years, participating in The Partnership has provided Diamondback with a forum to discuss and share our continuous monitoring efforts. Engagement with our peers about the technologies and tools they are using to drive down emissions continues to help inform our own efforts to monitor and mitigate emissions from our operations.”

Trevor Gleisner

Diamondback Energy

“Taking an active role as chair of the Measurement & Monitoring Workgroup has been a great experience as it has allowed me to quickly immerse myself within a group of experts that are present specifically to collaborate. This workgroup has shared solutions and obstacles for both large and small operators, creating a forum for open discussion, brainstorming, and recommendations.”

Kevin Turner

Continental Resources

“Thinking across silos opened up a new solution set, allowing us to use existing technology in a new way. This enables us to monitor for upset conditions with emissions potential, and allows our field partners to focus on the underlying root cause of any potential upset, so we can restore normal operating conditions faster.”

Katelyn Maxwell

Chevron

“Caterpillar is always in the pursuit of solutions to help customers perform at their highest level while remaining committed to building a better world. Participating in events like TEP’s Compressor Engine Roundtable allows us to get firsthand feedback from operators using our equipment to drive real change to continuously improve the services and equipment we provide.”

Rodney Harms

Caterpillar Oil & Gas

“CSU values our partnership with TEP, both TEP contributions to project cost share and TEP’s ability to convene multiple industry partners to discuss important issues. For example, this past year, we held a METEC workshop as part of TEP’s Annual Meeting and Conference to discuss how leak detection solutions should be tested and deployed. TEP convened a broader cross section of the industry than us contacting operators individually. This type of cooperation is instrumental getting the right inputs for this type of multi-stakeholder work.”