The Environmental Partnership’s seventh annual report demonstrates the U.S. oil and natural gas industry’s continued commitment to advancing environmental solutions. In 2024, TEP collective efforts built on the industry’s progress in reducing methane emissions, which declined 42% across U.S. onshore production regions between 2015 and 2023, according to the U.S. Environmental Protection Agency.

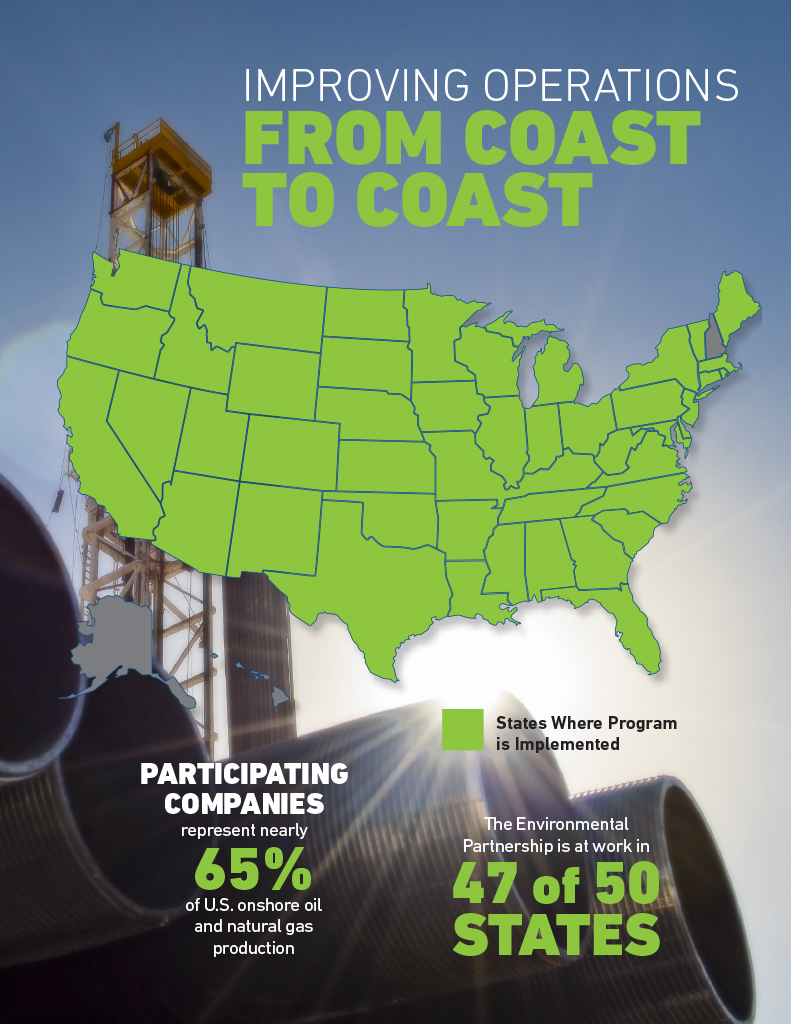

The Environmental Partnership, whose members represent nearly 65% of U.S. onshore oil and gas production, plays an instrumental role in supporting companies in their efforts to improve the industry’s environmental performance. The partnership fosters collective efforts that are built on sharing practices and leveraging knowledge between operators, partnering with other experts to further industry understanding, and working together to identify solutions, innovations and practices that reduce methane emissions across the supply chain.

See our progress in the 2025 Annual Report (19.8 MB).

2024 Performance Highlights

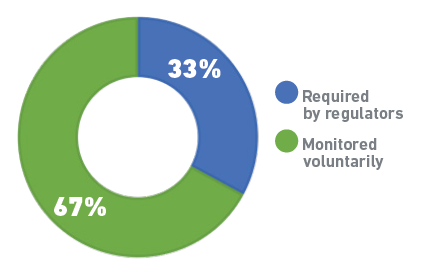

Advancing Emissions Detection and Monitoring Practices

Figure 1. The reported number of sites monitored by TEP companies in 2024 regulatorily and voluntarily.

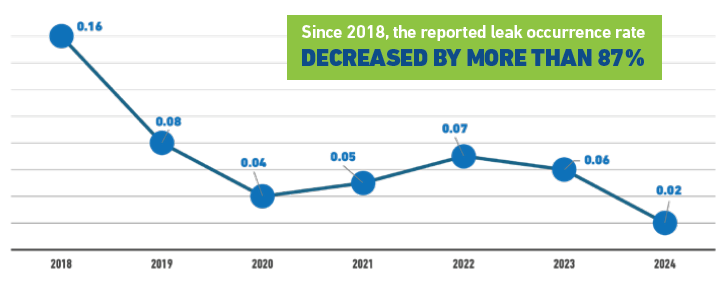

Figure 2. Leak Occurrence Rate

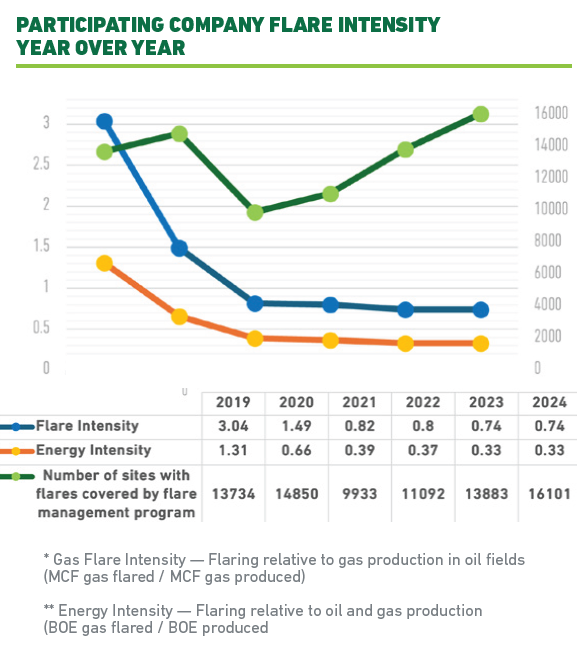

Promoting Flare Reduction and Efficiency Practices

Participating companies have made significant progress towards managing flare volumes, reducing their reported flare volumes by more than 75% since 2019, even as oil and natural gas production has increased.

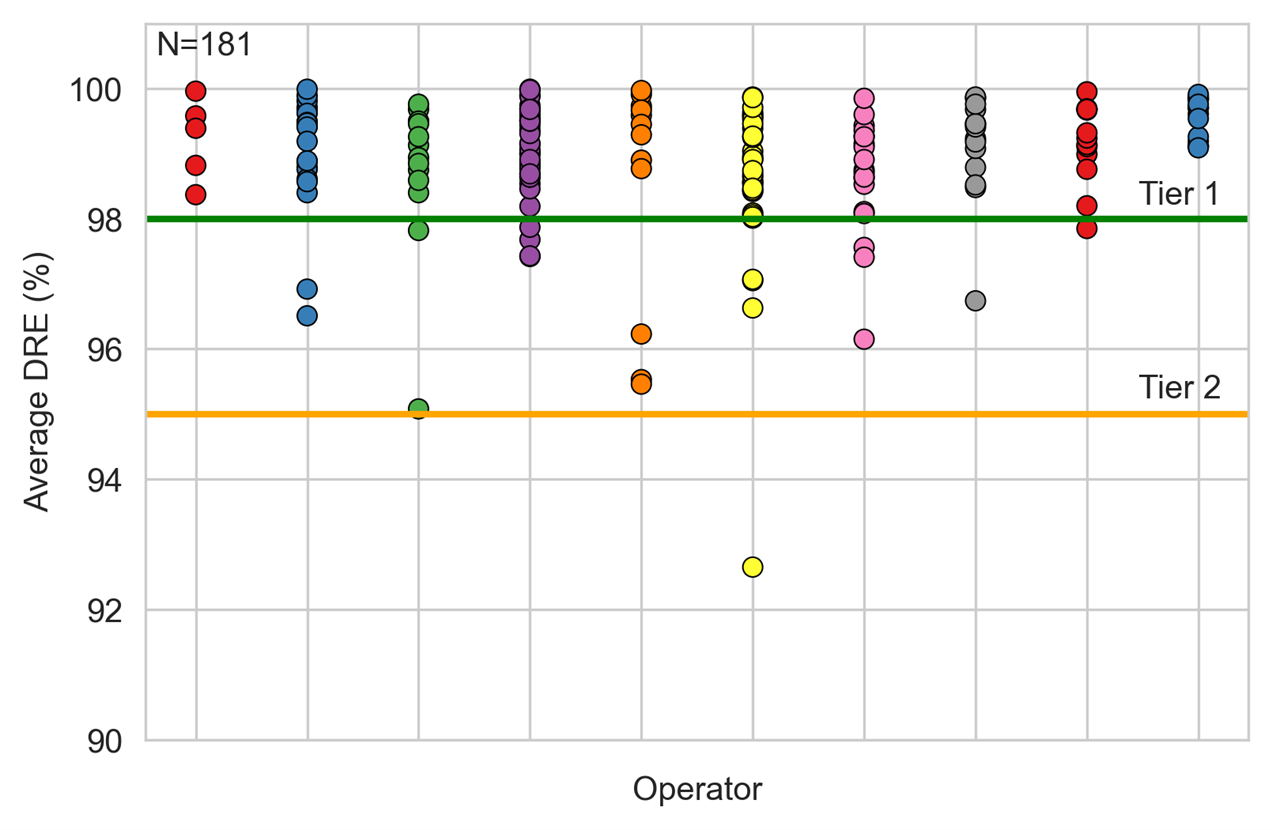

And a flare study conducted in 2024 highlighted operator attentiveness in flare maintenance and performance to reduce emissions, showing that for the flares tested, 88.95% were above 98% Destruction and Removal Efficiency (DRE) and 99.45% were above 95% DRE. These results suggest that using EPA’s default tier categorization for calculating emissions from flares may overestimate emissions.

Figure 3. Participating Company Flare Intensity Year over Year

Figure 4. VISR DRE measurements by anonymized operator for normal operations testing; illustrating EPA GHGRP tiered categorization

Taking Action

Reducing methane emissions is a complex puzzle with many pieces, and each puzzle is unique to an individual operator’s makeup. There is not “a one size fits all” solution. Companies implement different methane mitigation approaches and strategies based on basin and regional characteristics, types of assets, company size, and the company’s individual emissions reduction goals.

|

Tackling Methane emissions from Pneumatic Controllers |

Empowering Our Workforce to Drive Methane Intensity Reduction |

Developing a Hybrid Battery-Generator System |

|---|---|---|

| Learn about Chevron’s collaboration with Kathairos Solutions in the Denver-Julesburg basin to execute their largest methane emissions reduction project in 2024. | Discover how MPLX’s Methane Matters Campaign is aimed at educating their employees with knowledge, tools, and confidence to support their intensity reduction goals. | Find out how Oxy’s operational team faced a challenge with a remote oil production location and innovated their way to a solution. |

|

Implementing Tankless Design Solutions |

Targeting Flaring Practices to Achieve Emissions Reduction Goals |

Implementing Manual Liquid Unloading Practices |

|---|---|---|

| Dig into how Coterra has implemented innovative tank design solutions as part of their overall emissions reductions goals. | Learn about how Hess reduced flaring practices within its North Dakota operations. | Hear how Seneca Resources has taken a proactive approach in their emissions management since joining the partnership and continues to implement voluntary solutions. |

|

Enhancing LDAR Practices |

Enhancing Methane Monitoring Throughout the Appalachian Basin |

Building a Comprehensive LDAR Program |

|---|---|---|

| See how one of our newer participating companies, Elevation Resources, goes above and beyond regulatory requirements in leak repair and detection. | Read how EQT and other leading U.S. natural gas companies have partnered to form the Appalachian Methane Initiative (AMI) and the work the coalition has spearheaded in the region. | Check Out how PennEnergy’s Comprehensive LDAR program buildout across their assets in the Appalachian Basin. |

Taking Action

Reducing methane emissions is a complex puzzle with many pieces, and each puzzle is unique to an individual operator’s makeup. There is not “a one size fits all” solution. Companies implement different methane mitigation approaches and strategies based on basin and regional characteristics, types of assets, company size, and the company’s individual emissions reduction goals.

Tackling Methane emissions from Pneumatic Controllers

Learn about Chevron’s collaboration with Kathairos Solutions in the Denver-Julesburg basin to execute their largest methane emissions reduction project in 2024.

Empowering Our Workforce to Drive Methane Intensity Reduction

Discover how MPLX’s Methane Matters Campaign is aimed at educating their employees with knowledge, tools, and confidence to support their intensity reduction goals.

Developing a Hybrid Battery-Generator System

Find out how Oxy’s operational team faced a challenge with a remote oil production location and innovated their way to a solution.

Implementing Tankless Design Solutions

Dig into how Coterra has implemented innovative tank design solutions as part of their overall emissions reductions goals.

Targeting Flaring Practices to Achieve Emissions Reduction Goals

Learn about how Hess reduced flaring practices within its North Dakota operations.

Implementing Manual Liquid Unloading Practices

Hear how Seneca Resources has taken a proactive approach in their emissions management since joining the partnership and continues to implement voluntary solutions.

Enhancing LDAR Practices

See how one of our newer participating companies, Elevation Resources, goes above and beyond regulatory requirements in leak repair and detection.

Enhancing Methane Monitoring Throughout the Appalachian Basin

Read how EQT and other leading U.S. natural gas companies have partnered to form the Appalachian Methane Initiative (AMI) and the work the coalition has spearheaded in the region.

Building a Comprehensive LDAR Program

Check Out how PennEnergy’s Comprehensive LDAR program buildout across their assets in the Appalachian Basin.